When the Needle Meets Fabric: A Revolution in Strength and Color

In the rhythmic hum of a high-speed sewing line, every stitch counts. For professional sewers, a single thread break can halt production, cost time, and compromise quality. It’s in these demanding moments—when needles race through layers at 5,000 RPM—that ordinary threads fail. Enter the Premium 402 Polyester Sewing Thread, a quiet game-changer engineered not just to endure, but to elevate the entire sewing experience. Seamstresses and manufacturers alike are discovering that this isn’t merely thread—it’s reliability spun into every yard.

From Factory Floor to Sewing Machine: The Journey of a Superior Thread

Every spool of 402 thread begins as premium-grade polyethylene terephthalate, melted and extruded into ultra-fine filaments. These are precisely drawn, twisted for optimal tensile strength, and dyed using advanced immersion techniques that lock color deep within the fiber. By cutting out distributors and selling directly from the source, we ensure freshness, consistency, and pricing that reflects value—not markup. This vertical control means fewer variables, tighter quality checks, and a product that arrives exactly as it left the production line: flawless.

More Than Just Strong: The Five Hidden Advantages of 402 Thread

Beyond its impressive breaking strength, the 402 thread excels in ways most overlook. In independent lab tests, it demonstrated over 30% greater resistance to snapping under high-speed tension compared to standard polyester threads. Its color stability is equally remarkable—after 500 hours of continuous UV exposure, fading was nearly imperceptible, making it ideal for outdoor gear and sun-exposed garments. A proprietary lubrication coating reduces friction by up to 40%, minimizing heat buildup and eliminating skipped stitches. Whether gliding through heavy denim or delicate chiffon, the thread maintains integrity without shredding or puckering. And thanks to optimized winding density on the pagoda cone, unwinding is consistently smooth, reducing jams even during marathon sewing sessions.

Industrial Power, Perfectly Suited for Home Crafters

You don’t need a factory floor to benefit from industrial-grade performance. We spoke with three users whose needs span the spectrum. Maria, a production supervisor at a denim apparel plant, relies on 402 thread for its consistency across hundreds of daily seams. Elena, a bridal couture artisan, praises its clean finish on satin and lace—no lint, no fraying. Then there’s James, a weekend DIYer who uses it for custom tote bags and pet accessories. “I was shocked how well it runs on my家用 machine,” he says. “Once I adjusted the upper tension slightly and paired it with a matching bobbin thread, it stitched like butter.” For home users, we recommend a moderate presser foot pressure and testing on scrap fabric first—small tweaks unlock professional results.

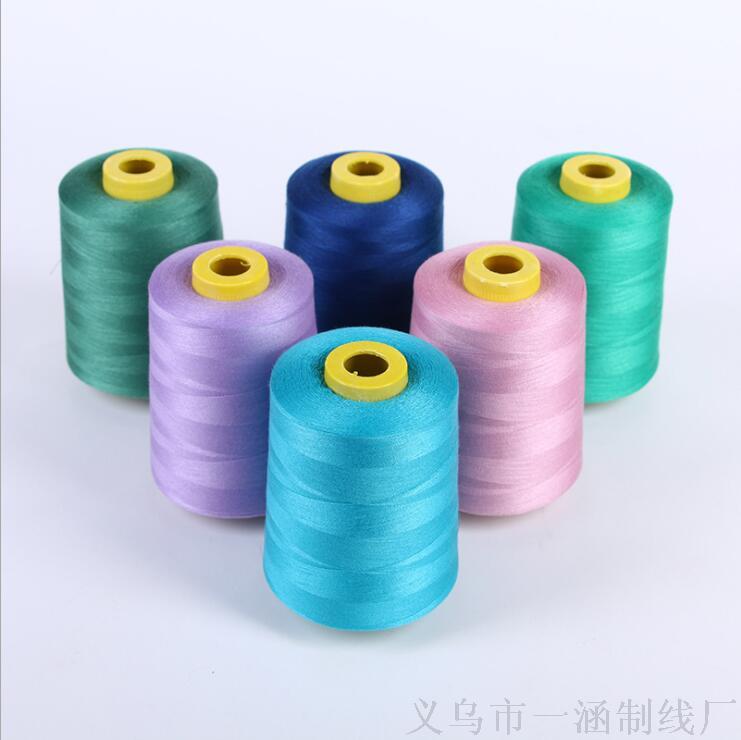

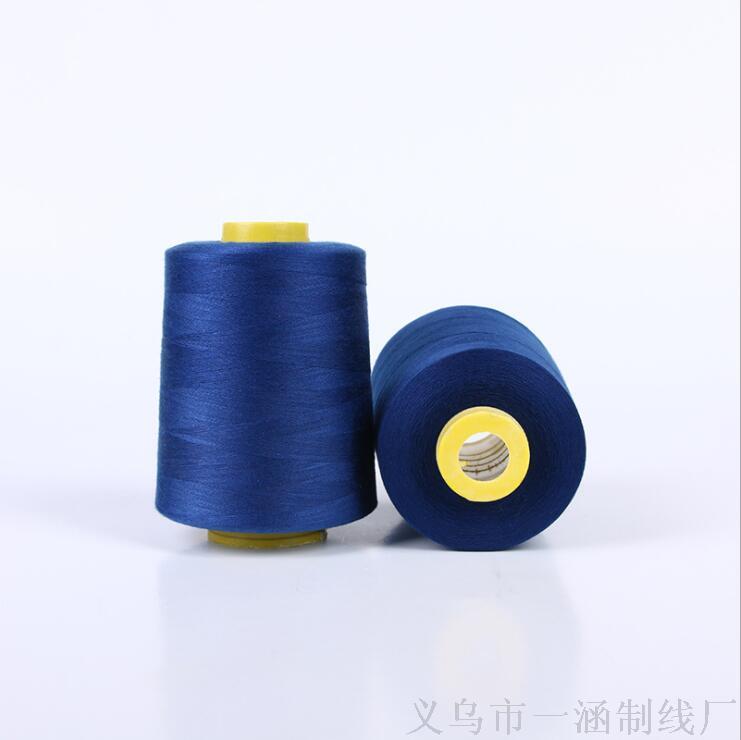

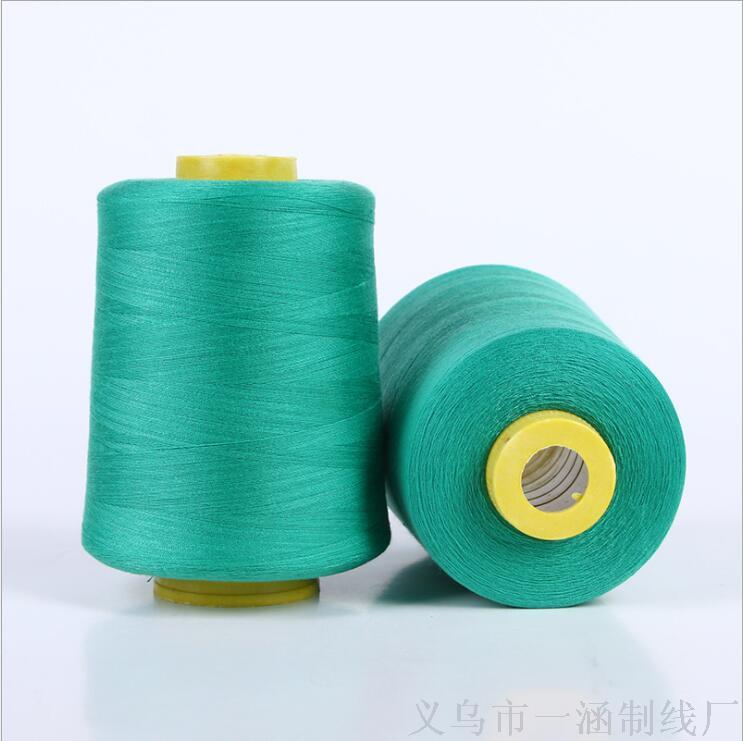

Color as Function: Where Beauty Meets Performance

Vivid hues aren’t just aesthetic—they’re functional. Using eco-friendly disperse dyes and molecular penetration technology, our threads achieve deep saturation without compromising wash or light fastness. Our design team analyzes seasonal fashion trends and workwear standards to curate palettes that match market demand. Looking for drama? Try the reflective gold for stage costumes. Need durability with distinction? The deep navy is a favorite among utility and tactical gear makers. Each shade undergoes rigorous batch testing to ensure chromatic consistency across thousands of spools.

The Details You Don’t See—but Will Always Feel

True quality lives in the unseen. The iconic pagoda-shaped cone isn’t just traditional—it’s functional, preventing tangling and ensuring even payout under tension. Inside every sealed pack, a humidity-control film protects against moisture, crucial in tropical or rainy climates where mildew can weaken fibers. Before shipping, every batch undergoes spectrophotometric analysis and tensile sampling, guaranteeing that your second order matches your first down to the micron.

Redefining Durability: Tested in the Real World

One outdoor brand subjected seams stitched with 402 thread to extreme cycling between -30°C and 60°C—simulating Arctic winters and desert summers. After 200 cycles, seam integrity remained intact, with zero thread degradation. In side-by-side pull tests, 402 outperformed generic polyester by nearly 50% in breaking strength. Customers echo this resilience: “I’ve used nothing else for three years,” writes a upholstery restorer. “Even my repair technician asked what thread I use—he sees the difference in machine wear.”

The Future of Thread: Sustainable, Smart, Seamless

The next generation of 402 thread is already in development—now incorporating recycled PET from post-consumer bottles without sacrificing strength. As smart sewing machines emerge with tension-sensing and conductivity requirements, we’re exploring anti-static treatments and integrated data tags for traceability. Our factory now employs real-time digital monitoring, tracking everything from dye lot temperature to winding speed, so every spool is not only consistent but fully traceable from raw material to final packaging.

The Premium 402 Polyester Sewing Thread isn’t just keeping pace with modern sewing—it’s setting the standard. Whether you're building brands or building dreams, one thing is clear: the strongest seams begin with the right thread.