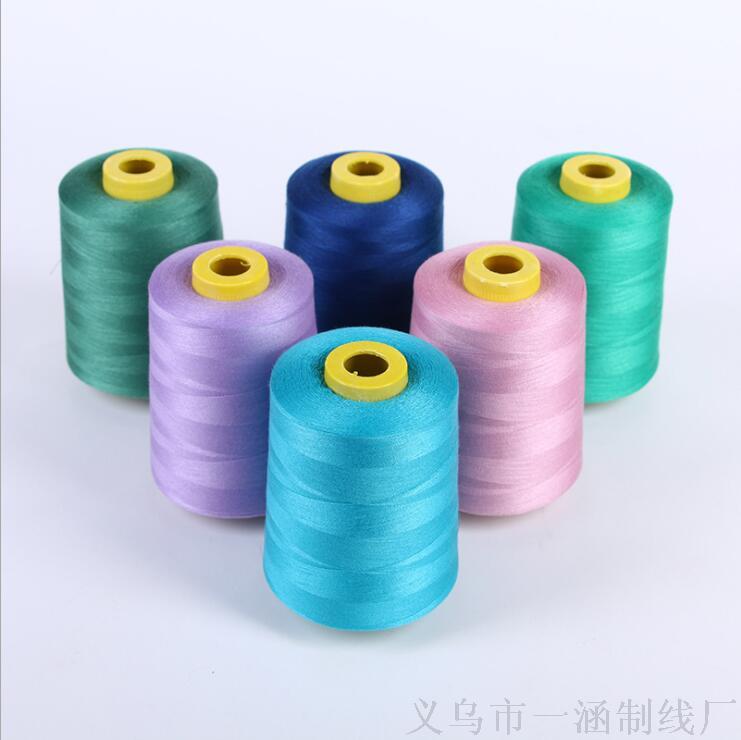

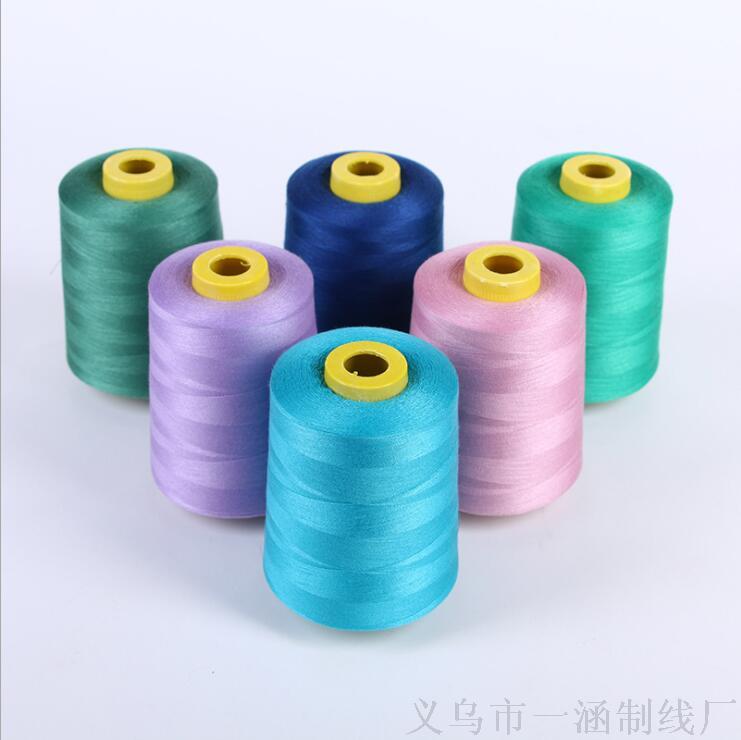

Factory Direct 402 Polyester Sewing Thread – High-Speed, Colorfast & Machine Ready

Vibrant, durable, and ready to perform — the 402 polyester thread powers precision stitching across industries.

Vibrant, durable, and ready to perform — the 402 polyester thread powers precision stitching across industries.

From Factory Floor to Sewing Machine: The Extraordinary Journey of a Thread

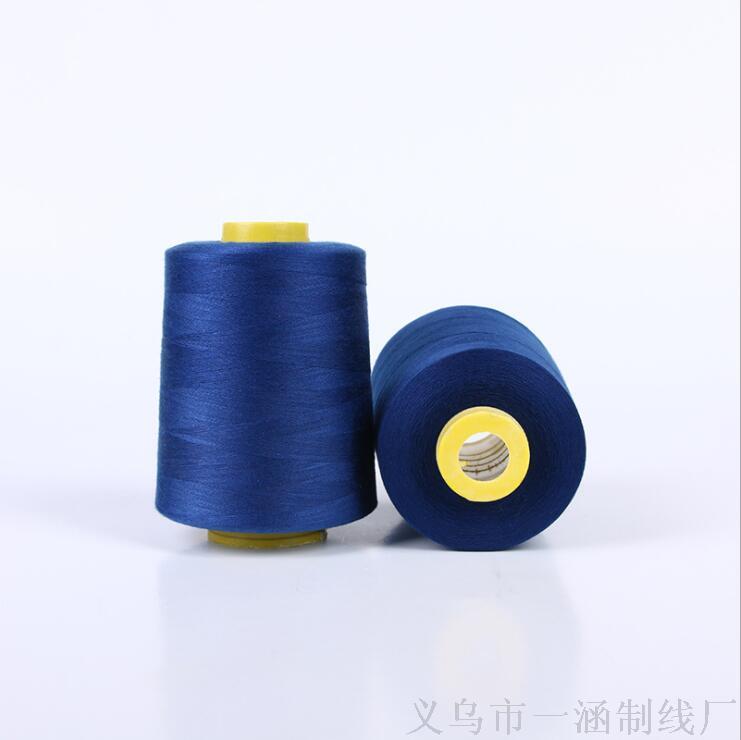

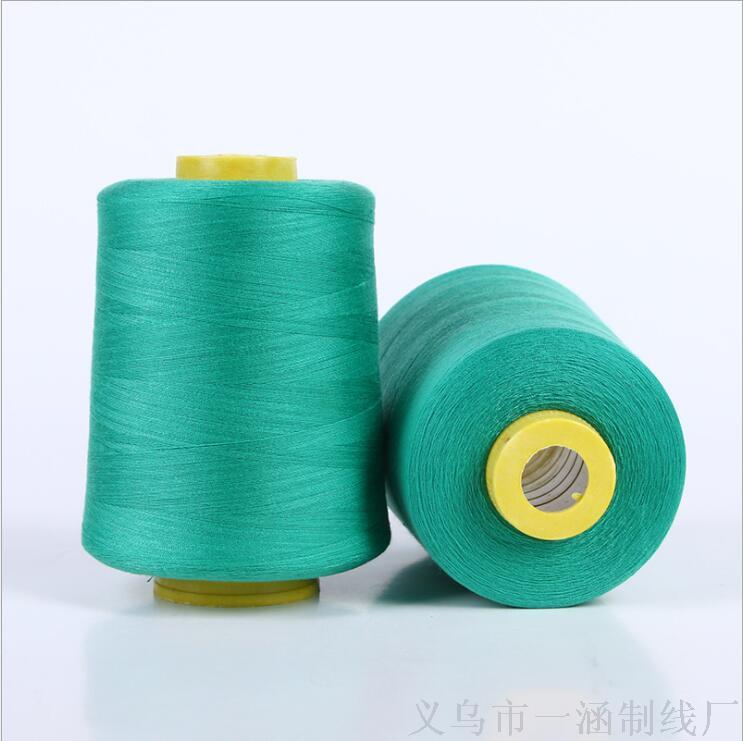

I remember waking up not in cotton fields or silkworm cocoons, but in a stream of molten polymer under precise thermal control. I am 402 polyester sewing thread — born from refined PET granules, drawn through micro-dies with micron-level accuracy, then twisted into strength. My creation isn’t accidental; it’s engineered. Each filament is pulled, cooled, and aligned to resist stretching and heat, ensuring consistency from the first stitch to the thousandth. In industrial dye baths exceeding 130°C, I absorb color deep into my core — not just on the surface. By the time I’m wound onto the spool, I’m already dreaming of高速 (high speed), tension, and purpose.

A Symphony of Speed and Strength: Designed for High-Speed Mastery

In modern garment production, every second counts. Machines spin at over 5,000 RPM, demanding threads that won’t snap under stress. This is where the 402 shines. Its high-tension air-entangled structure locks filaments together without weakening them — no loose fibers, no fraying ends. Unlike traditional cotton threads that degrade quickly under friction and heat, 402 maintains integrity even during marathon runs. We tested side-by-side: after eight hours of continuous operation, cotton-based threads showed visible wear and multiple breaks, while 402 completed the same task with zero interruptions. For factories aiming for throughput without compromise, this isn’t an upgrade — it’s essential infrastructure.

Seamless performance at high speeds — 402 thread thrives where others fail.

Seamless performance at high speeds — 402 thread thrives where others fail.

Color That Doesn’t Quit: When Beauty Meets Industrial Durability

Designers know that true luxury lies in longevity. A vibrant red should still scream confidence after fifty washes. That’s why premium fashion studios choose 402 for their limited-edition collections. Through advanced thermosol dyeing and pigment encapsulation, color becomes part of the fiber itself. UV exposure? Saltwater immersion? Repeated laundering? These are challenges met, not feared. One designer in Barcelona told us she uses only 402 for her hand-finished jackets — “The thread doesn’t just match the fabric,” she said, “it outlasts trends.”

Behavior Under Pressure: How 402 Performs Across Fabrics

It’s one thing to work well on canvas, another to glide through delicate voile without puckering. We put 402 to the test across four demanding materials: heavyweight denim, stretchy Lycra blends, synthetic leather, and sheer chiffon. On denim, it powered through multiple layers without shredding. With knits, its slight elasticity prevented seam popping. Even on slick PU leather, where many threads skip or jam, 402 maintained consistent feed thanks to its smooth coating. Pro tip: reduce presser foot pressure slightly on ultra-thin fabrics, and pair with a sharp needle — you’ll achieve near-invisible seams every time.

The Unsung Hero Behind the Scenes

Walk into any large-scale apparel factory, and you’ll find pallets of 402 thread feeding automated lines. But its impact goes beyond volume. A veteran sewing machine technician from Ho Chi Minh City shared a telling observation: “Since switching to 402, we’ve cut downtime due to thread breaks by 70%. Machines run cooler, needles last longer, and maintenance intervals have stretched significantly.” Even bespoke shoemakers rely on it — one artisan in Florence uses 402 for attaching soles, citing its resistance to moisture and abrasion as critical for longevity.

Precision stitching on tough denim — proof of 402’s reliability under strain.

Precision stitching on tough denim — proof of 402’s reliability under strain.

Sustainable Strength: Eco-Conscious Without Compromise

Durability doesn’t have to come at the planet’s expense. Today’s 402 thread incorporates up to 30% recycled polyester, sourced from post-consumer bottles. Meanwhile, closed-loop dye systems minimize water waste, reducing effluent by over 60% compared to conventional methods. To crafters asking whether toughness means toxicity, the answer is now a clear no. You can build heirloom-quality pieces knowing the thread beneath supports both your vision and environmental responsibility.

When Creativity Meets Unbreakable Support

Meet Maria, a quilt artist from Portland who uses 402 for intricate machine embroidery — “It holds complex patterns without bobbin jams.” James, a bridal tailor in London, trusts it for invisible hemming on silk gowns. And Leo, an outdoor gear modder, reinforced his backpack straps with triple-stitched 402 — later joking he used the same spool to suspend a model bridge between two bookshelves (it held 15 pounds). These aren’t isolated cases — they reflect a growing trust in a thread that empowers bolder making.

Craftsmanship meets performance — artisans rely on 402 for precision and durability.

Craftsmanship meets performance — artisans rely on 402 for precision and durability.

The Thread of Tomorrow: What’s Next?

As smart textiles emerge, could 402 evolve beyond passive stitching? Imagine threads with embedded micro-sensors detecting seam stress in real-time, or antimicrobial finishes for medical apparel. Perhaps future versions will change color with temperature or signal when tension drops mid-sew. While today’s 402 sets the benchmark, innovation never rests. When engineering reaches its peak, the next leap may come not from material alone, but from how we reimagine the role of thread — not just as a connector, but as a collaborator in creation.