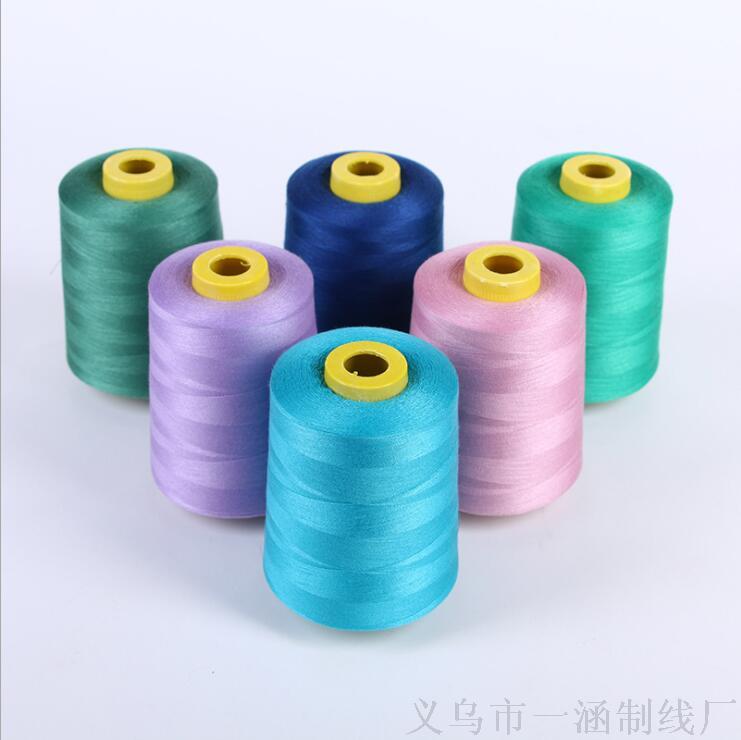

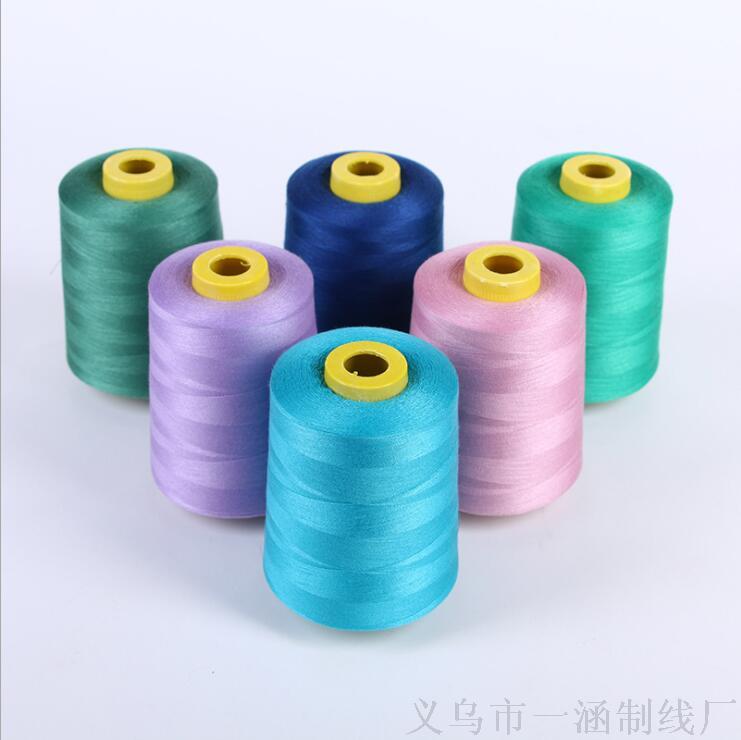

Vibrant, consistent colors meet industrial strength in every spool of 402 Polyester Sewing Thread.

When Speed Meets Color: Redefining the Industrial Standard in Sewing Thread

In today’s fast-paced textile world, the demand for both efficiency and aesthetic excellence has never been higher. Modern sewing isn’t just about holding fabric together—it’s about doing so at breakneck speeds while maintaining flawless appearance. Traditional threads often buckle under pressure, fraying or snapping when pushed beyond moderate speeds. That’s where the Factory Direct 402 Polyester Sewing Thread steps in as a true game-changer. Engineered from the ground up for resilience and visual richness, this thread doesn’t just keep up with high-performance machines—it enhances them.

From Factory to Needle Tip: The Journey of an Exceptional Thread

Bypassing intermediaries isn’t just a cost-saving move—it’s a quality assurance strategy. When you choose factory-direct thread, you’re getting a product that moves straight from controlled production lines to your sewing table. Each spool begins with premium-grade polyester filaments, selected for tensile integrity and chemical purity. Through advanced drawing and twisting processes, these fibers are transformed into a tightly coiled, uniform structure designed to resist tangling and maintain consistent thickness.

Microscopic precision in fiber alignment ensures smooth feeding and minimal friction during high-speed operation.

Rigorous testing is embedded in every batch. Threads undergo dynamic tension assessments, abrasion resistance trials, and UV exposure simulations to guarantee performance under real-world conditions. This commitment to quality control means every spool delivers reliability you can trust—whether you're stitching prototypes or producing thousands of units daily.

Built for Speed: Dynamic Performance in High-RPM Machines

At 5,000 stitches per minute, many standard threads begin to fail—kinking, breaking, or creating skipped seams. The issue? Poorly balanced internal stress and inconsistent diameter. The 402 Polyester Thread solves this with a high-density缠绕 (winding) structure that promotes seamless unwinding and reduces friction against machine parts. Its low-lint profile keeps your bobbin area clean, minimizing downtime for maintenance.

In practical tests across zigzag, buttonhole, and lockstitch patterns, the 402 thread demonstrated superior stability. Even under continuous heavy-load operation, it maintained stitch integrity without puckering or seam distortion—making it ideal for automated production lines where consistency equals profitability.

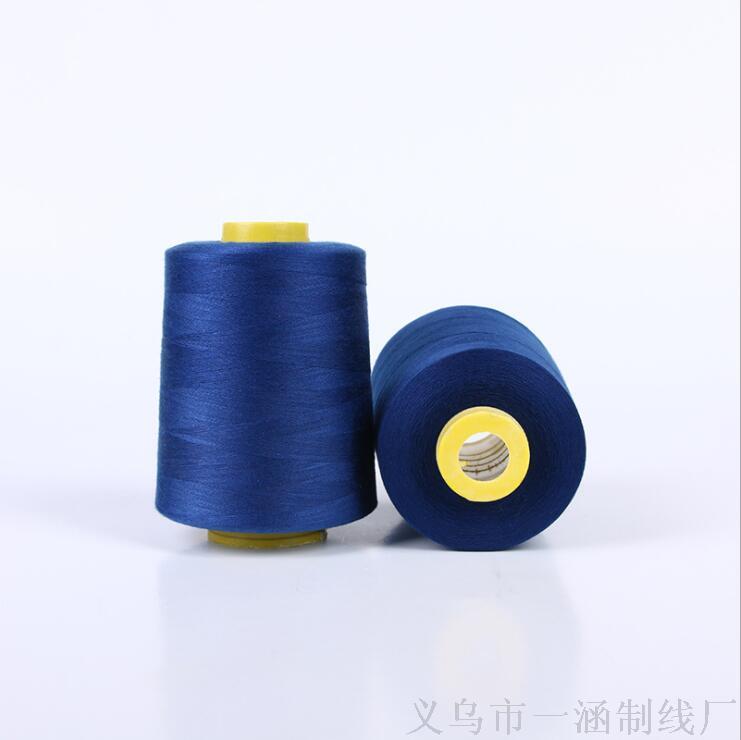

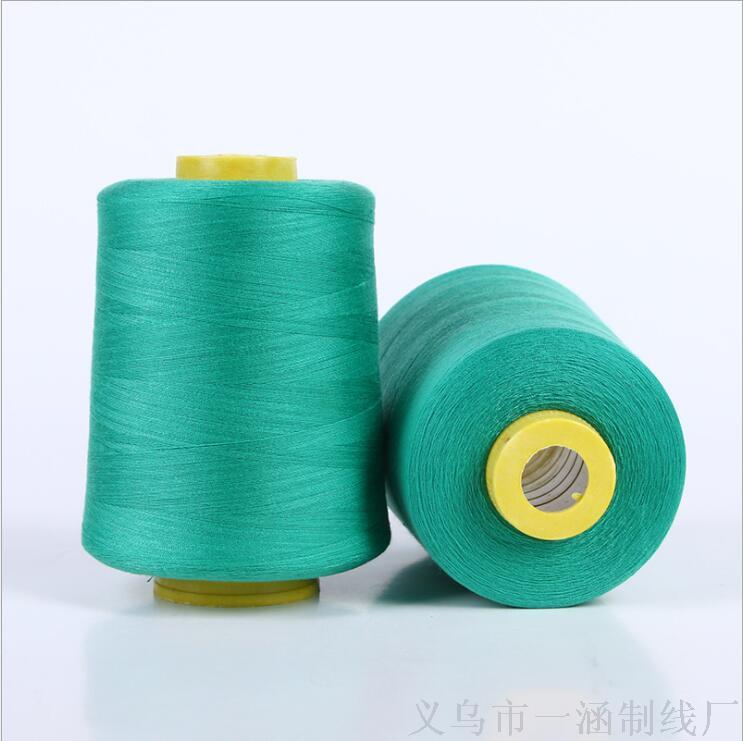

More Than Durability: A Canvas of Living Color

Color isn't an afterthought—it's engineered into every fiber. Our dedicated dye lab utilizes a proprietary "memory dye" technology that bonds pigments deep within the polyester core. This isn’t surface-level coloring; it’s molecular integration that resists fading even after 200 hours of direct sunlight exposure. Reds stay bold, blues remain deep, and blacks retain their luster wash after wash.

A spectrum of fade-resistant hues ready for fashion, upholstery, and technical textiles.

For brands, this color consistency translates directly into value. Imagine producing a run of denim jackets or bridal gowns where every seam matches perfectly across batches. No more costly reworks due to shade variations. With 402 thread, what you see in the first sample is exactly what you’ll get in the thousandth unit.

A Versatile Performer: From Factory Floors to Home Studios

While built for industrial environments, the 402 thread has found enthusiastic fans among home sewists and crafters. One apparel manufacturer reported a 30% reduction in thread-related stoppages after switching—translating to significant time and cost savings. Meanwhile, hobbyists appreciate its clean running behavior on domestic machines like Brother, Juki, and Singer models. Simply adjust your tension settings slightly, and you’re set for professional-grade results.

The Hidden Details That Define Longevity

True quality lies beneath the surface. Internal stress management during manufacturing prevents torque buildup—a common cause of seam puckering over time. Additionally, the thread’s anti-pilling, low-fuzz design minimizes fiber shedding, which not only keeps garments looking newer longer but also reduces lint accumulation in machine components.

And when it comes to care, this thread stands firm. With near-zero shrinkage, it withstands repeated hot-water washing and high-heat ironing without compromising seam strength—essential for uniforms, workwear, and children’s clothing.

Precision stitching with no fraying or weakening—proof of superior thread engineering.

Weaving the Future, One Stitch at a Time

Sustainability drives innovation. Our production process incorporates energy-efficient extrusion methods, and packaging is increasingly shifting toward recyclable materials. But we don’t stop there. Real user feedback—from factory supervisors to indie designers—shapes each iteration of the 402 thread. Looking ahead, we’re exploring conductive fibers and smart-thread applications tailored for wearable tech and responsive fabrics. Because the future of sewing isn’t just faster or stronger—it’s smarter.

The Factory Direct 402 Polyester Sewing Thread isn’t just another supply item. It’s the invisible foundation of durable, beautiful craftsmanship. Whether you're powering through production runs or perfecting a handmade masterpiece, every stitch tells a story of precision, passion, and progress.